Lever for Stock (L4S)

Identify and quantify how much better your inventory can improve

What are the Benefits of Using the

Lever4Stock?

Optimize Inventory Management

Minimize stockouts, reduce excess inventory, and achieve better control over your stock levels, leading to lower holding costs and improved cash flow.

Boost Profitability

Increase inventory turns and maximize GMROI (Gross Margin Return on Investment) by aligning inventory with actual demand and supply conditions.

Enhance

Decision-Making

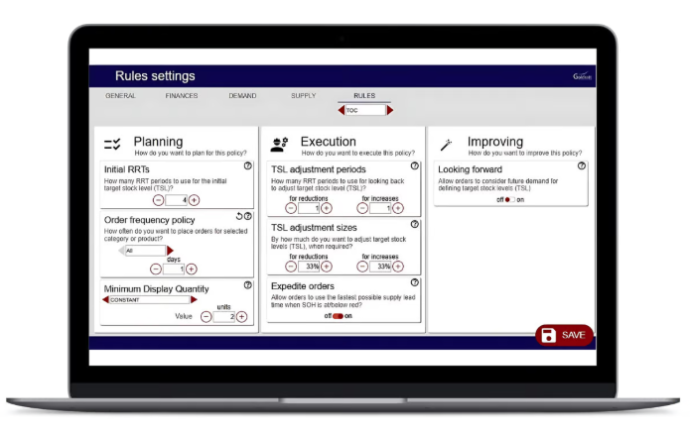

Simulate various scenarios to identify the best inventory management rules tailored to your specific business environment

Reduce Costs

Identify avoidable shortages and surpluses, cutting down on unnecessary expenses related to overstocking, waste, or emergency shipments.

More features

1.

Scalable Solution

Suitable for single stock locations or complex supply chains, making it adaptable to businesses of any size.

2.

Risk-Free Testing

Explore "what-if" scenarios without impacting real-world operations, enabling better planning for unexpected disruptions or demand spikes.

3.

Data-Driven Insights

Gain actionable insights into inventory performance, including SKU analysis, bottlenecks, and variability, empowering your team to make informed decisions.

4.

Improve Customer Satisfaction

Maintain optimal stock levels to meet customer demand, reducing stockouts and ensuring timely deliveries.

5.

Support for Strategic Planning

Use L4S to test and refine strategies for product launches, replenishment policies, and discontinuation decisions.

What decisions does L4S help me make?

How much inventory should we keep?

Determining the initial inventory amount can lead to two potential mistakes: keeping too much stock, resulting in unnecessary costs, or not having enough stock, leading to lost sales opportunities.

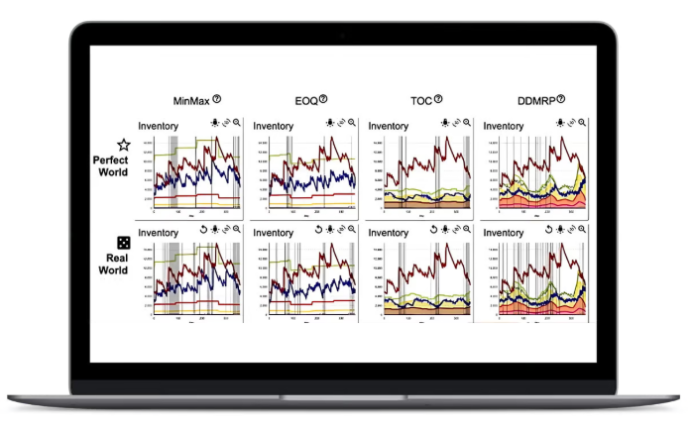

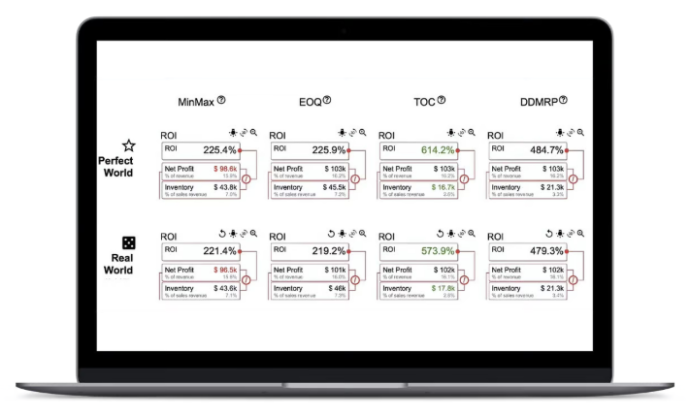

With our L4S, you can directly compare these rules for YOUR company’s specific customer demand and supply lead time profiles and to ensure you select the “best” rule for each product location.

When should we change the target stock level, and if we should, by how much?

With so much variability in demand and supply, it can be hard to differentiate between noise and signal. When there's a significant shift in demand or supply, adjusting the target stock levels is critical to avoid unnecessary excess or surplus inventory. But knowing when and by how much you should change the target stock level is a complex problem.

When deciding the new target stock level, you might change it when it's not necessary, or you don't adjust the target stock levels when they need to be changed.

Our L4S allows you to simulate and test various rules for deciding when and how much to change target stock levels to find the most optimum rule for each product location.

When should we stop keeping stock of this item?

Two possible mistakes can be made when deciding when to stop keeping stock of a product: maintaining inventory for too long, thereby tying up cash and wasting precious shelf space, OR discontinuing it prematurely while it's still garnering profitable sales.

Consumer Goods Companies are constantly under pressure to launch new products. Managing the release of new products or new models can be very challenging to get right. And products don't always perform equally well in various stores or regions. How do we know when to replace an existing product with a new product?

With L4S, you can test various rules for deciding when to replace products to ensure the products you have in stock that occupy space and cash has the highest sales velocity and GMROI (Gross-Margin-ROI).

Our Goal: 5X Return On Investment

Guaranteed 5X ROI or Your Money Back: We are so confident in the value our L4S will deliver, that if, within the first semester, our L4S doesn’t identify opportunities for at least a 5x ROI, we’ll provide a pro-rata refund. For instance, if you invested $10,000 in the L4S, and it did not help you identify more than$50,000 in additional free cash flow, we’ll provide a pro-rate refund.

Average results on some implementations:

40%

Less inventory

35%

More sales

98%

Availability

30%

Lower total costs

Are you ready to boost your inventory management performance?

Our L4S has helped numerous organizations optimize their inventory management, reducing stockouts, and minimizing overstock costs.

Get Started Today.